A preventive maintenance schedule is a vital tool for any organization looking to keep its equipment and facilities running smoothly. By implementing a regular maintenance plan, businesses can prevent costly breakdowns, extend the lifespan of their assets, and improve overall efficiency.

In this article, we will explore the benefits of preventive maintenance and provide practical tips on how to create and implement an effective schedule.

What is a Preventive Maintenance Schedule?

A preventive maintenance schedule is a planned routine of inspections, repairs, and replacements that are performed on equipment and facilities to prevent potential issues and ensure optimal performance. It involves systematically checking for signs of wear and tear, performing necessary maintenance tasks, and documenting the actions taken.

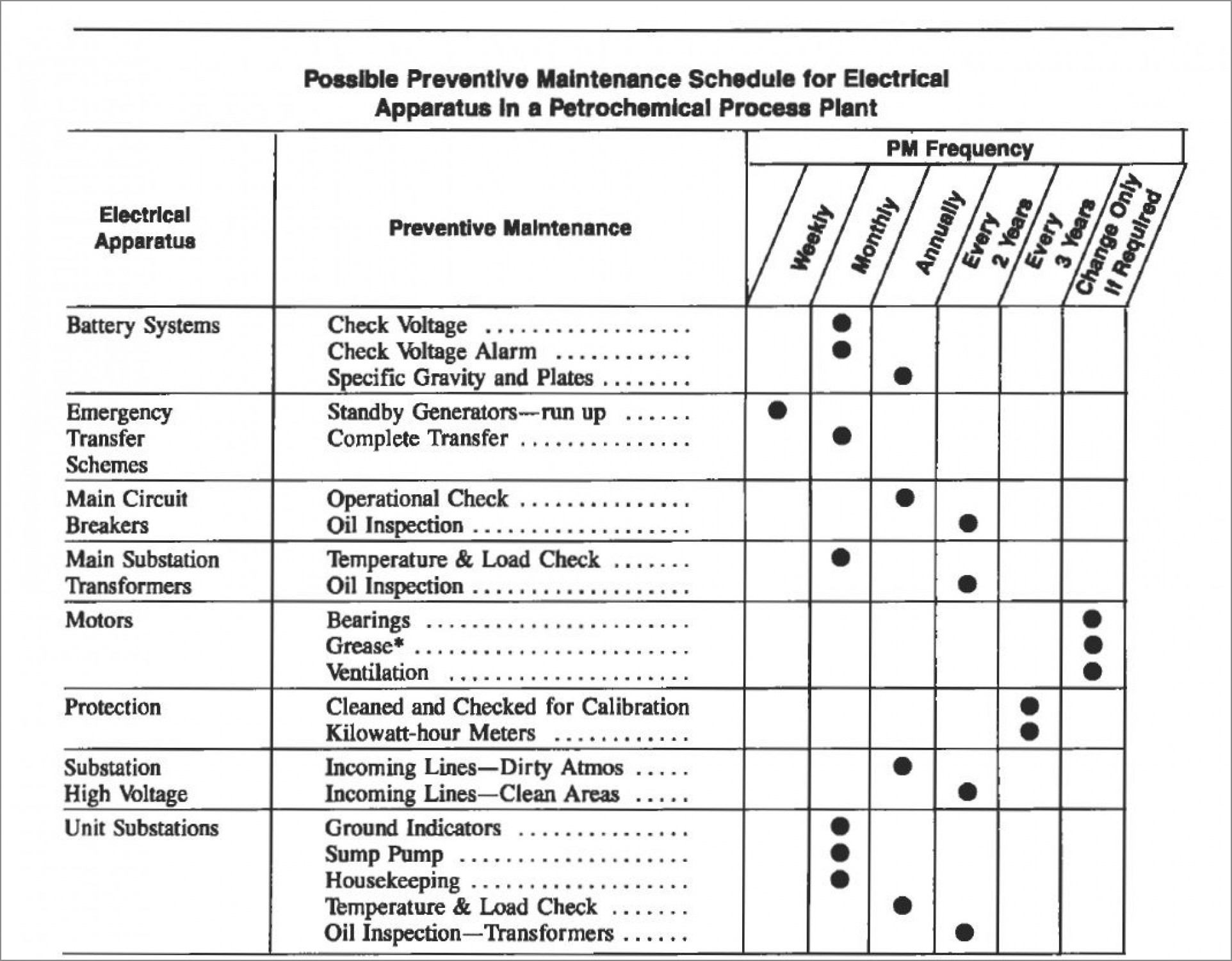

A preventive maintenance schedule typically includes regular tasks such as lubrication, filter changes, cleaning, and inspections. It can also involve more comprehensive activities like calibrations, parts replacements, and system upgrades. The frequency of these tasks may vary depending on the type of equipment and its usage.

Why Should You Implement a Preventive Maintenance Schedule?

Implementing a preventive maintenance schedule offers numerous benefits for businesses. Here are some compelling reasons why you should consider adopting this proactive approach:

- Reduced Downtime: Regular maintenance helps identify and address potential issues before they turn into major problems, reducing unexpected breakdowns and downtime. This can save businesses significant amounts of time and money.

- Extended Equipment Lifespan: By consistently maintaining equipment, you can prolong its lifespan and avoid premature replacements. This can result in substantial cost savings in the long run.

- Improved Safety: Regular inspections and maintenance ensure that equipment is operating safely, minimizing the risk of accidents and injuries in the workplace.

- Enhanced Efficiency: Well-maintained equipment operates more efficiently, leading to improved productivity and reduced energy consumption.

- Compliance with Regulations: Certain industries have specific maintenance requirements mandated by regulations or governing bodies. By implementing a preventive maintenance schedule, businesses can ensure compliance and avoid legal issues.

How to Create an Effective Preventive Maintenance Schedule

Creating an effective preventive maintenance schedule requires careful planning and consideration. Here are the key steps to follow:

1. Assess Your Equipment and Facilities

Start by conducting a thorough assessment of all the equipment and facilities that require maintenance. Identify the critical assets that have the most significant impact on your operations and prioritize them in your schedule.

2. Determine Maintenance Frequencies

Consider the manufacturer’s recommendations, industry standards, and your own experience to determine how often each piece of equipment should be inspected and maintained. Some factors to consider include usage intensity, environmental conditions, and potential risks.

3. Define Maintenance Tasks

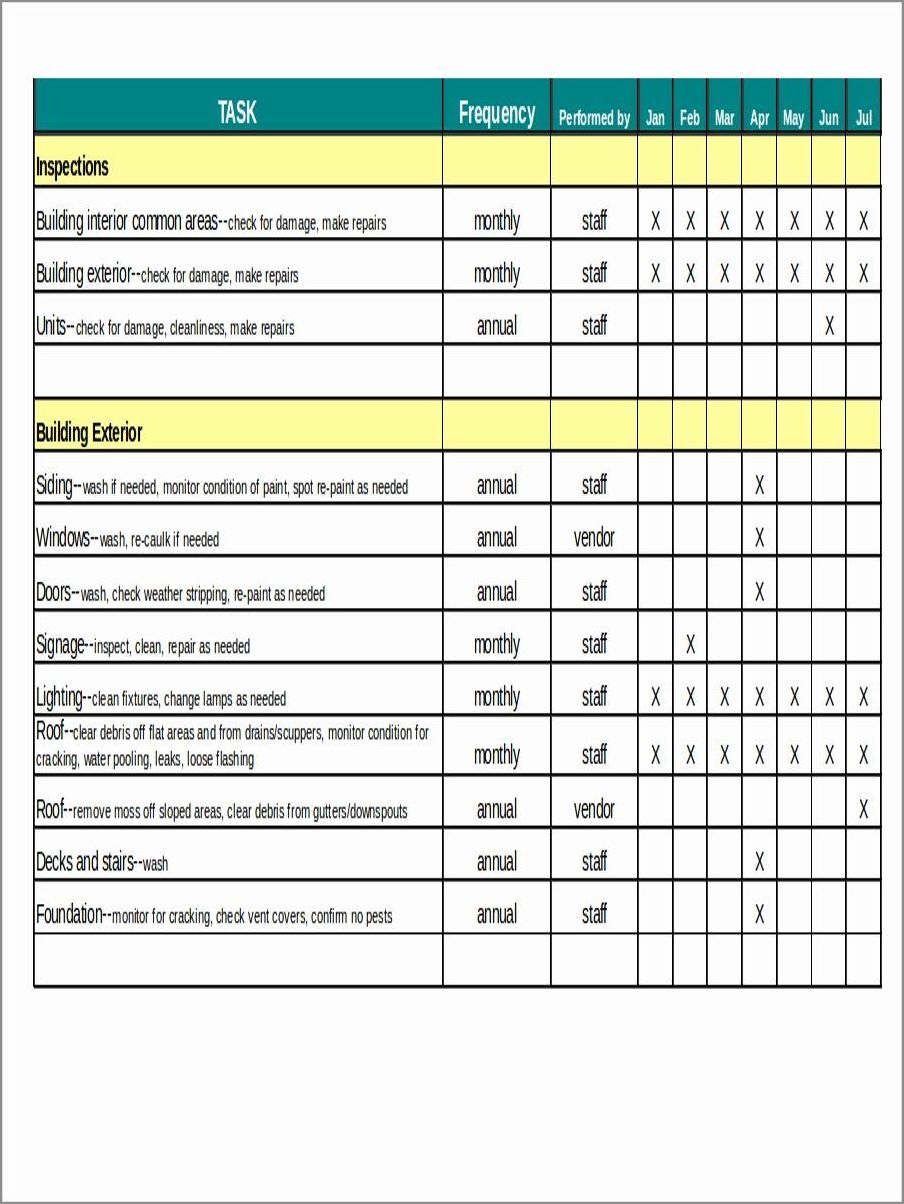

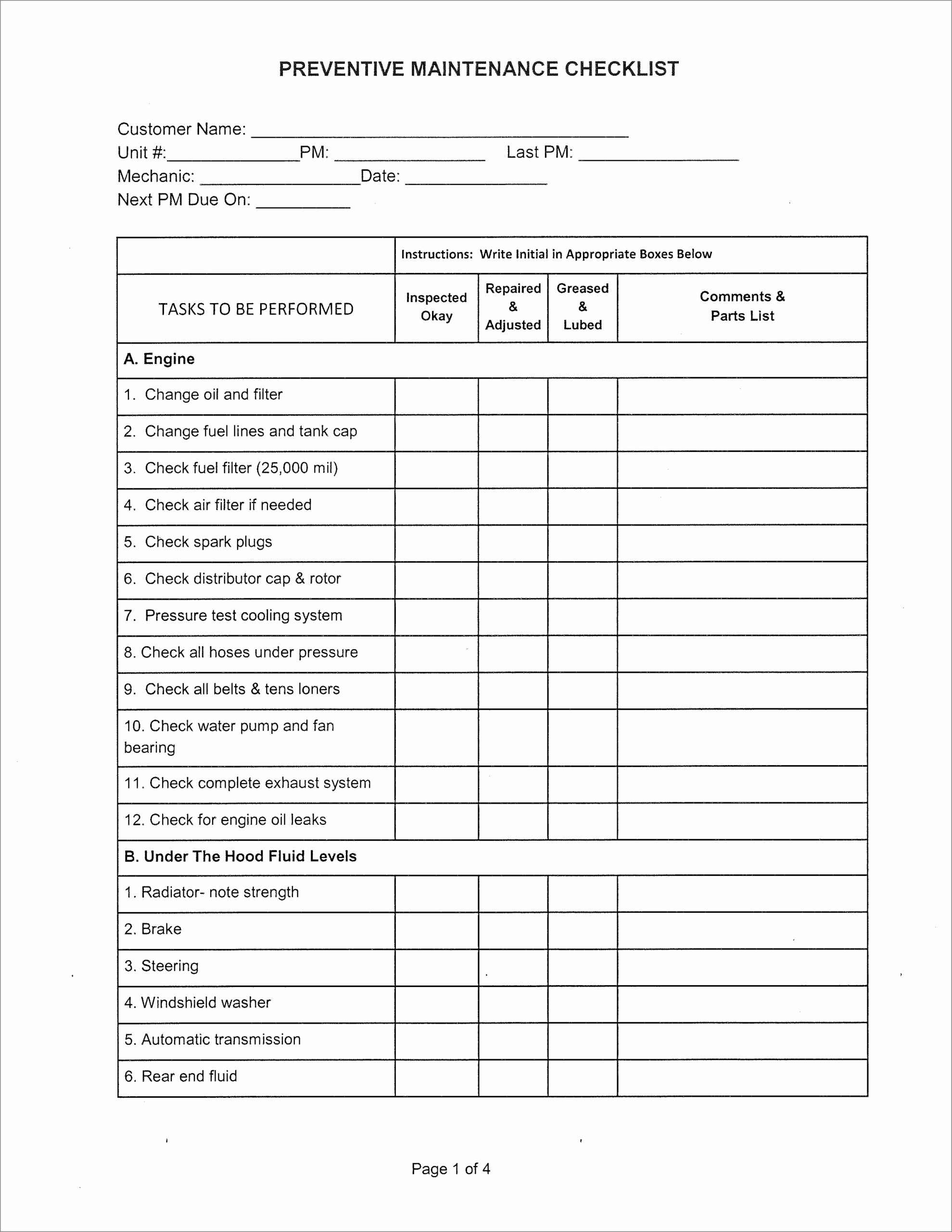

List all the specific maintenance tasks that need to be performed for each asset. This could include tasks such as cleaning, lubricating, inspecting, calibrating, and replacing parts. Be as detailed as possible to ensure nothing is overlooked.

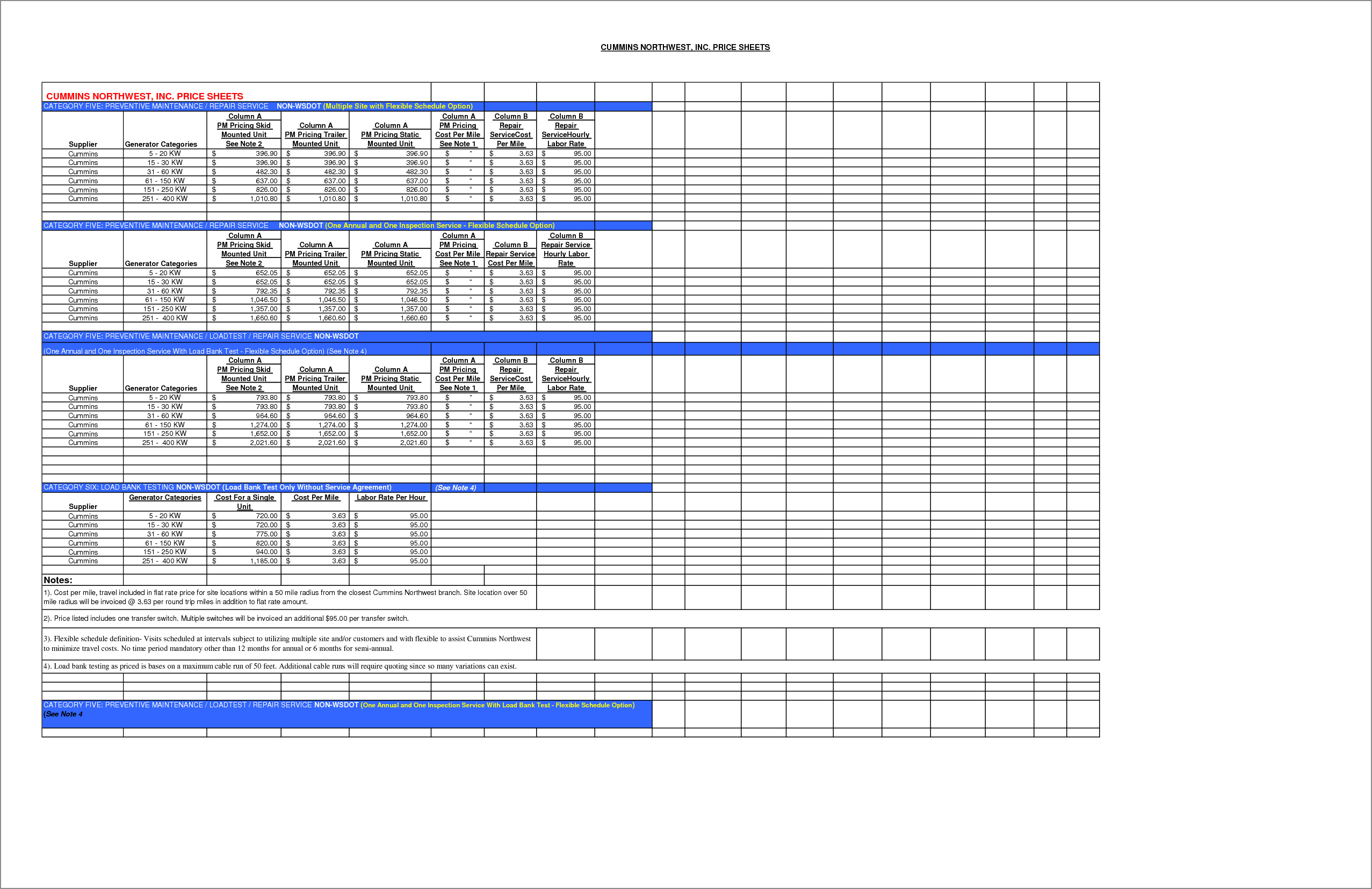

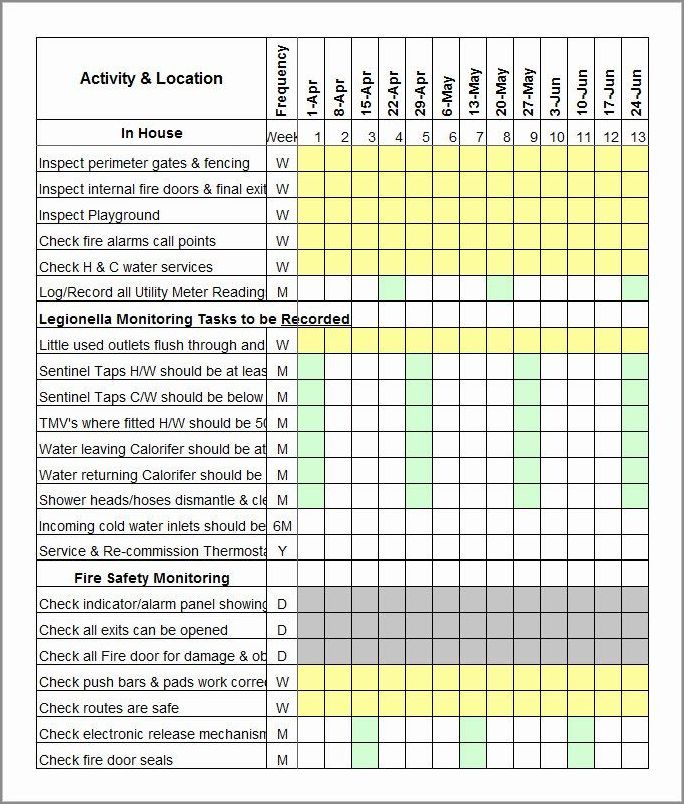

4. Create a Schedule

Organize the maintenance tasks into a schedule that outlines when each task should be performed. Consider the availability of resources, such as personnel and spare parts, when creating the schedule. Use a calendar or a computerized maintenance management system (CMMS) to help you manage and track the schedule.

5. Assign Responsibilities

Clearly define who is responsible for performing each maintenance task. Assigning responsibilities ensures accountability and helps prevent tasks from being overlooked or duplicated.

6. Train and Educate Staff

Provide training and education to the maintenance team and other relevant staff members. Ensure they understand the importance of the preventive maintenance schedule and how to perform the required tasks correctly and safely.

7. Document and Track Maintenance Activities

Keep detailed records of all maintenance activities, including the tasks performed, dates, and any issues encountered. This documentation will help you track the history of each asset, identify recurring problems, and make informed decisions about future maintenance actions.

Examples of Preventive Maintenance Schedules

Here are two examples of preventive maintenance schedules for different industries:

1. Preventive Maintenance Schedule for a Manufacturing Facility

- Monthly: Inspect and clean machinery, check lubrication levels, and tighten loose connections.

- Quarterly: Replace filters, inspect electrical systems, and perform calibration checks.

- Bi-annually: Conduct comprehensive inspections, replace worn-out parts, and perform system upgrades.

2. Preventive Maintenance Schedule for a Fleet of Vehicles

- Weekly: Check tire pressure, fluid levels, and lights. Inspect brakes and perform basic cleaning.

- Monthly: Change engine oil and filters, inspect suspension components, and lubricate moving parts.

- Annually: Conduct comprehensive inspections, replace worn-out parts, and perform emission tests.

The Bottom Line

A preventive maintenance schedule is a proactive approach to ensuring the smooth operation of equipment and facilities. By implementing a regular maintenance plan, businesses can prevent costly breakdowns, extend equipment lifespan, improve safety, and enhance overall efficiency. Creating an effective preventive maintenance schedule requires careful planning, documentation, and accountability. By following the steps outlined in this article, you can create a schedule that meets your organization’s needs and maximizes the benefits of preventive maintenance.

Preventive Maintenance Schedule Template Excel – Download